Artificial Rice Production Line

Brand : Shengrun

Product origin : Jinan, China

Delivery time : 20-30 days

Supply capacity : 30 sets/month

1. frequency speed controlling with high automation and stable performance. 2. The screws are made of alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demands. 4. The forced lubrication system, can guarantee the equipment transmission life longer. 5. Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise. 6. Self-cleaning, when stopping, it can be cleaned without disassembling.

Artificial rice can be two types. One type is re-shapped rice from broken rice. Another type is nutritional rice or we can call it functional rice.

In the rice milling factories, there are large quantity of broken rice which can only be grinded to rice powder for selling, or be sold with much lower price on the market. So, broken rice is a very headache problem for rice mill owners. Our extruders take rice powder for extrusion and shaping. It is an solution for broken rice.

"Nutritional rice" and "Functional rice" is nutrients combined rice. The raw materials mixture can be rice, corn, starch, cereals, milk, medicines, herbs, spices, sugar, vietamins, etc. This nutritional rice can be cooked within a few minutes, and contains more necessary nutrient than natural rice of which human bady required.

1. Artificial rice samples:

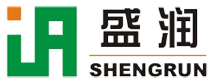

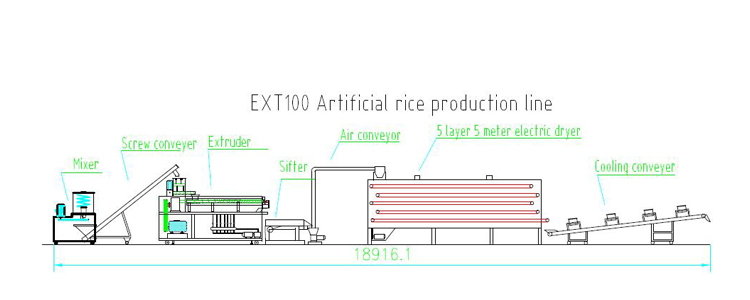

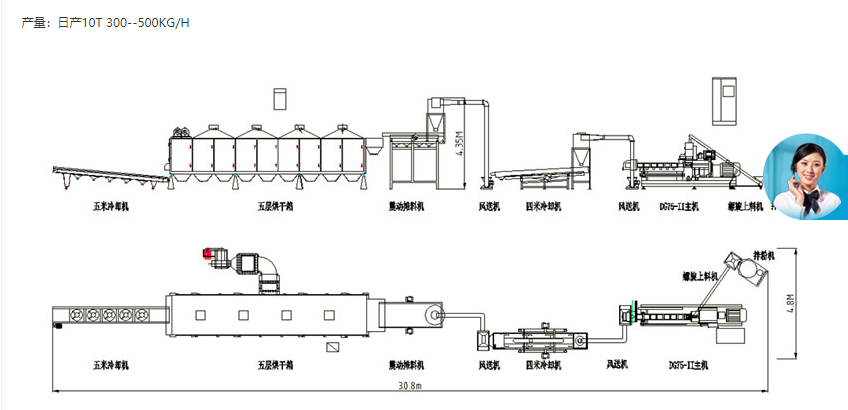

2. Artificial rice production lines flowchart:

a. 100kg/hr Single screw extrusion line

Mixer → Screw conveyer → Single-screw extruder → Vibrating cooler → Air conveyer → 5 meter 5 meter drying oven → Cooling conveyer → Packing machine(optional)

b. 200kg/hr Double-screw extrusion line

Mixer → Screw conveyer → Extruder → Vibrating cooler → Air conveyer → 5 meter 8 meter drying oven → Cooling conveyer → Packing machine(optional)

3.Video of production artificial rice:

4. Technical parameters:

| Model | EXT100 | TSE70 | TSE75 | TSE95 |

| Capacity | 100kg/hr | 200kg/hr | 350kg/h | 800kg/h |

| Installed power | 90kw | 115kw | 130kw/h | 190kw/h |

| Dimension | 22×2×3 m | 25×2.5×3 m | 29×2.5×3 m | 35×2.5×3 m |

| (L×W×H) |

5. Our service:

(1) Free consultation service for all processes;

(2) Free project planning and design services;

(3) Free debugging till every machine running well;

(4) Free delivery management for loading, shipment and transportation;

(5) Free workers training of equipment maintenance and operating;

(6) Free new production techniques and formulas after sales;

(7) 1 year complete warrantee and lifetime maintenance service and cost price spare parts.

6. Customer visiting:

7. After service photos

8. Packaging and Delivery:

A. We will pack all necessary machines into wooden cases. For drying machine, and heavy extruders, we will fix them in the container with very strong iron wire.

B. If by LCL for small quantity machines, we will let send to QINGDAO port for loading.

C. If need containers, our trucks will take the containers from port to our factory for professional and safely loading, and then return to port for shipment.

6. Shengrun company certificates:

Related articles: