Biodegradable Packing Foam Peanuts Production

Brand : Jinan Shengrun

Product origin : Jinan China

Delivery time : 15-30 days

Supply capacity : 30/month

1.Packaging foam peanuts production machines uses cheap natural starch,maize/corn starch and tapioca starch as main materials,through extruding treatment process,to produce multi-functional and high-valuable biodegradable packing materials. Its double screw extruder is special designed,consists of 6 systems: feeding system, extruding system,cutting system,heating system,conveying system and cooling system, its barrels and screws structure can easily realize the function of changing the properties of the starch.

Eco-friendly Packaging Foam Peanuts Production machine

1.Packaging foam peanuts production machines uses cheap natural starch,maize/corn starch and

tapioca starch as main materials,through extruding treatment process,to produce multi-functional

and high-valuable biodegradable packing materials. Its double screw extruder is special

designed,consists of 6 systems: feeding system, extruding system,cutting system,heating

system,conveying system and cooling system, its barrels and screws structure can easily realize

the function of changing the properties of the starch.

2.Raw materials of packaging foam peanuts production machines:

Maize / Corn starch, Cassava /Tapioca starch, Potato starch

3.Products of packaging foam peanuts production machines: corn starch loose filler, biodegradable packing peanuts,resilient &reusable stuffing materials, water soluble & compostable cushioning materials.

4.Flow Chart of packaging foam peanuts production machines

Mixer Machine---Screw Conveyor---Twin-screw Extruder---Air Conveyor---Drying Machine

5.Technical Parameter of packaging foam peanuts production machines

| Model | TSE65 | TSE70 | TSE95 |

| Installed Power | 55kw | 70kw | 120kw |

| Power Consumption | 40kw | 50kw | 95kw |

| Production Capacity | 100-150kg/h | 200-300kg/h | 600-800kg/h |

| Dimension | 19000*1300*2200mm | 21000*1300*2200mm | 30000*1500*2600mm |

6. All the machines are made by stainless steel, this line is with reasonable design and high

automation; the screws are made by alloy steel, with building block system structure and self-

cleaning function.

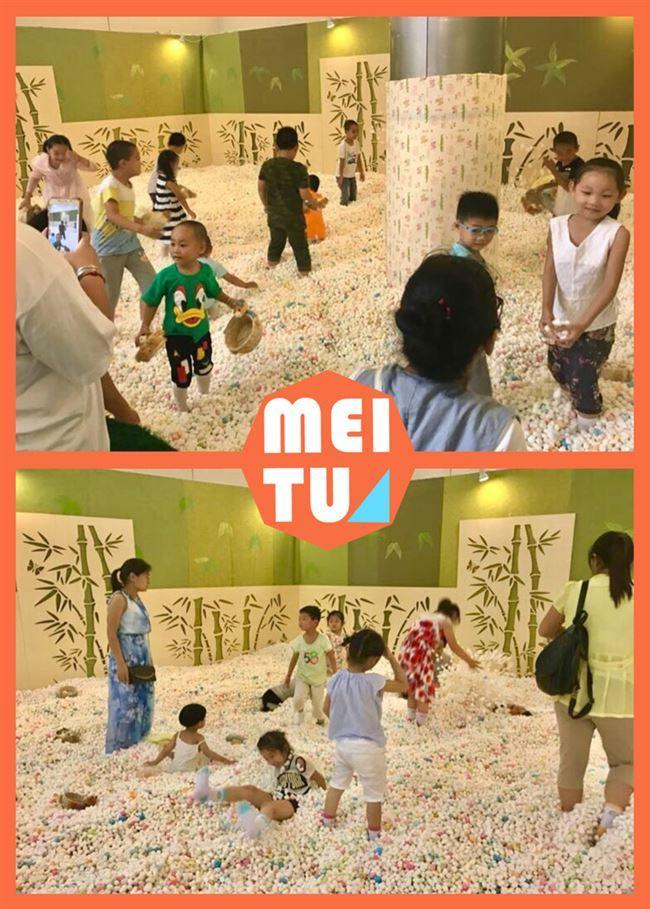

7. Sample pictures