Three-screw Extruder Machine

Brand : Jinan Shengrun Machinery

Product origin : Jinan China

Delivery time : Within 15 days

Supply capacity : 50 sets per month

1. High output and low energy consumption. 2. The gearbox has a long life. 3. Self-cleaning function. 4. The frequency converter speed regulation technology 5. Long life of screw 6. Automatic lubrication system 7. Internal mixing function and good dispersion effect 8. Good exhaust performance

The development of extruder has gone through a process from single-screw extruder to twin-screw extruder to today's tri-screw extruder. The emergence of the twin-screw not only improves the production efficiency, but also expands the application scope of the extruder; now the birth of the triple-screw has further improved the production efficiency, but also allowed the extruder to enter a more subdivided production field, and produce more refined products. The extrusion system of the three-screw extruder is composed of three screws with a barrel, and the three screws can be arranged in parallel or in a triangle according to requirements. Compared with the twin-screw extruder, there is one more screw, the meshing area is increased, and the corresponding production efficiency is further improved. The application of three-screw extruders in the food industry and pet food industry is increasing.

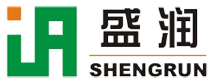

Details of Three-screw Extruder:

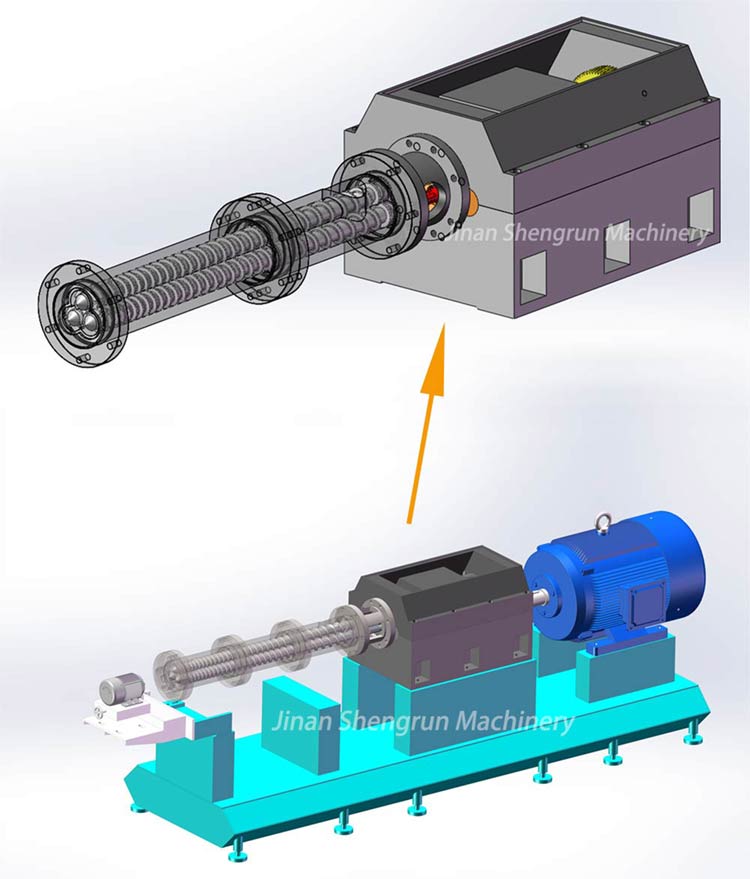

The Three-screw Extruder is Assembled:

Features of Three-screw Extruder:

1. High output and low energy consumption

The two screws of the twin-screw extruder form one meshing surface, while the three screws of the three-screw extruder form three meshing surfaces, that is, the meshing area of the screws of a three-screw extruder is equivalent to three sets of the same power twin-screw extruders’ screw meshing area, so the extrusion efficiency and shearing efficiency is high, and its output is twice that of the twin-screw extruder with the same power. To produce the same quantity of products, the cost of manpower, space, etc. is doubled reduced. And it saves energy because the power of the main motor, heating coil and other components is reduced.The gearbox has a long life

2. The gearbox has a long life

Compared with the twin-screw extruder, the inside of the gearbox of the three-screw extruder adds a force point, the force area of the box increases, and the corresponding pressure decreases, thereby prolonging the life of the gearbox.

3. Self-cleaning function

The machine has an automatic cleaning function, and the waste in the barrel can be cleaned without disassembling the screw when the machine is stopped.

4. The frequency converter speed regulation technology

The extruder machine adopts advanced frequency converter speed regulation technology, which makes the equipment powerful, runs more smoothly and saves electricity.

5. Long life of screw

The screws are treated with alloy steel nitriding, the life of the screw is longer, and the individual equipment adopts the building block combination structure, which can be combined arbitrarily according to different needs.

6. Automatic lubrication system

Automatic lubrication system to ensure a longer life of the transmission part of the equipment.

7. Internal mixing function and good dispersion effect

The three screws are arranged in a triangle, forming a hermetic space in the central area. With the rotation of the screw, the material is continuously transferred between the screws and the closed space. Between the screws, the material is subjected to strong extrusion and shearing, and the pressure exerted on the material in the hermetic space is reduced, so that repeated shearing and crushing, plus the high temperature generated by the extrusion, the material is uniformly dispersed and matured.

8. Good exhaust performance

There is no material accumulation in the exhaust port of the machine, and there is no material leakage or blockage. The reason is that the material is almost sucked into the hermetic space in the center of the screw. The hermetic space here is equivalent to a melt pump, so it will not leak out. Therefore, the machine can achieve a high degree of vacuum and improve the quality of the product.

Technical Parameters:

| Model | Applicable Scope | Installed Power | Main Motor Power | Capacity | Dimension |

TSE65-3 | Feed Production | 56kw | 45kw | 300kg/h | 2480x900x1900mm |

Food Production | 56kw | 45kw | 250kg/h | 2480x900x1900mm |

Compare With Twin-screw Extruder

| Model | Applicable Scope | Installed Power | Main Motor Power | Capacity | Dimension |

TSE65 | Feed Production | 35kw | 22kw | 150kg/h | 2480x900x1900mm |

Food Production | 35kw | 22kw | 100kg/h | 2480x900x1900mm |

Video of tri-screw extruder produce puffed corn sticks:

What Product can be produced by triple-screw extruder?

Pet food such as dog food, cat food, fish feed, frog feed, bird feed; puffed snacks such as cheese ball, corn stick, Bugle snack, Doritos.